Products

Perforated steel strip PE pipe Yekupa mvura

Application

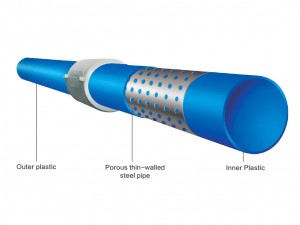

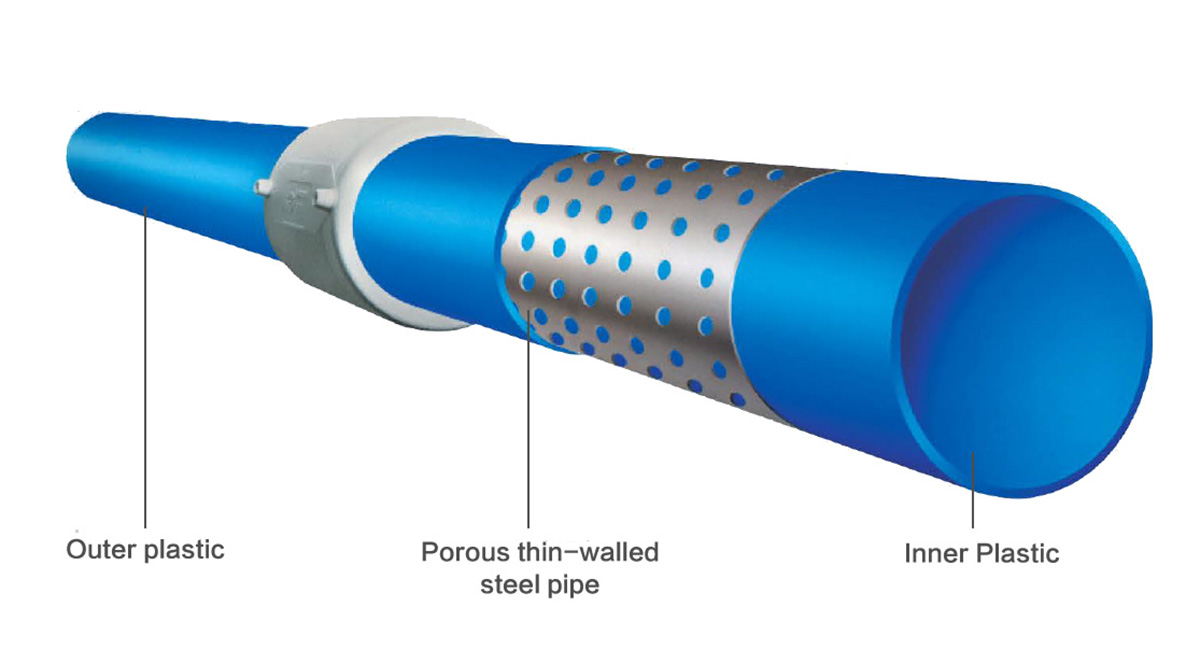

Perforated simbi strip polyethylene composite pombi inogadzirwa neinotonhora-yakakungurutswa strip simbi uye thermoplastics seyakagadzirwa, uye porous yakatetepa-yakavakirwa simbi mapaipi akaumbwa neargon arc butt welding kana plasma spiral welding anoshandiswa sekusimbisa. Iwo ekunze uye emukati akaturikidzana ane maviri-sided composite thermoplastics. Rudzi rutsva rwepombi yekumanikidza pombi, Nekuti iyo porous yakatetepa-yakavakirwa simbi pombi yekusimbisa yakaputirwa muinoenderera thermoplastic, iyi inoumbwa pombi haingokunda zvakakanganisika zvepombi dzesimbi nemapombi epurasitiki, asiwo ine kusimba kwepombi dzesimbi uye ngura. kushorwa kwepombi dzepurasitiki. Ndiyo mhinduro ye petroleum nemakemikari maindasitiri. Iyo pombi inodiwa nekuchimbidza yemapombi makuru uye epakati-dhayamita akaomeswa muminda yemishonga, chikafu, migodhi, gasi nemimwe minda. Iri zvakare shanduko yekuvandudza tekinoroji kugadzirisa pombi huru yekuvaka uye kupihwa kwemvura yemanisipala. Irwo rudzi rutsva rwepombi inosanganiswa mu21stzana remakore.

Features

High simba uye yakaderera mutsara kuwedzera.

Nekuda kwekusimbaradzwa kwesimbi furemu, iyo perforated simbi strip plastiki composite pombi ine yakakwirira simba, yakakwirira rigidity uye kukanganisa kuramba kupfuura pombi yepurasitiki. Panguva imwecheteyo, kuzvidzora kwechigadziro chesimbi kunoitawo kuti perforated steel strip plastiki composite pipe ine а mutsara wakaderera wakafanana neyo pombi yesimbi. Kuwedzera coefficient uye сгеер kuramba.

Corrosion uye kusapfeka.

Iyo yakakwira-density polyethylene zvinhu zvakasarudzirwa perforated simbi strip plastiki composite pombi icrystalline isiri-polar polymer zvinhu ine yakagadzikana makemikari zvimiro, kuramba kune yakawanda acid, alkali munyu uye organic media, uye по electrochemical corrosion. Kugaya kuita kwakapetwa kashanu kupfuura iyo mapaipi esimbi.

Technical Parameters

Ichi chigadzirwa chinoshandisa yakakosha polyethylene resin, uye yayo yemuviri uye michina zvivakwa zvinosangana neBazi rekuvaka chiyero CJ/T181-2003 uye indasitiri yemakemikari chiyero HG/T3706-2014.

| Tsanangudzo saizi, kutsauka uye kudzvanywa kwezita: kusangana nezvinodiwa zveMinistry yekuvaka chiyero CJ/T181-2003. | |||||

| Zita rekunze dhayamita uye kutsauka | Nominal rusvingo ukobvu uye kutsauka | Kunze kwekutenderera | Nominal pressure | Minimum S kukosha | Hurefu nekutsauka |

| Dn(mm) | En(mm) | Mm | Mpa | Mm | mm |

| 50+0.5 0 | 4.0+0.5 9 | 1.0 | 2.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5+0.6 0 | 1.26 | 2.0 | 1.5 | |

| 75+0.7 0 | 5.0+0.7 0 | 1.5 | 2.0 | 1.5 | |

| 90+0.9 0 | 5.5+0.8 0 | 1.8 | 2.0 | 1.5 | |

| 110+1.0 0 | 6.0+0.9 0 | 2.2 | 2.0 | 1.5 | |

| 140+1.1 0 | 8.0+1.0 0 | 2.8 | 1.6 | 2.5 | |

| 160+1.2 0 | 10.0+1.1 0 | 3.2 | 1.6 | 2.5 | |

| 200+1.3 0 | 11.0+1.2 0 | 4.0 | 1.6 | 2.5 | |

| 225+1.4 0 | 11.5+2.4 0 | 4.5 | 1.6 | 2.5 | |

| 250+1.4 0 | 12.0+1.3 0 | 5.0 | 1.6 | 3.5 | |

| 280+1.5 0 | 12.5+2.6 0 | 5.6 | 1.6 | 3.5 | |

| 315+1.6 0 | 13.0+1.4 0 | 6.3 | 1.25 | 3.5 | |

| 355+1.6 0 | 14.0+2.8 0 | 7.1 | 1.25 | 3.5 | |

| 400+1.6 0 | 15.0+1.5 0 | 8.0 | 1.25 | 3.5 | |

| 500+1.7 0 | 16.0+1.6 0 | 10.0 | 1.0 | 4.0 | |

| 630+1.8 0 | 17.0+1.7 0 | 12.3 | 1.0 | 4.0 | |

| Cherechedza: Kudzvinyirirwa kwezita repombi inosanganiswa ndiyo yakanyanya kudzvinyirira inobvumirwa kuti pombi itakure mvura pa20 ° С. Kana tembiricha ichichinja, kumanikidza kwekushanda kunofanirwa kugadziridzwa zvinoenderana neiyo tembiricha yekumanikidza coefficient yezvinhu zvakasiyana. S kukosha: chinhambwe kubva kunze kwedhayamita yekusimbisa kusvika kune kunze kwepombi. | |||||

| Zvenyama uye zvemuchina kuita zvinodiwa | ||

| Project | Performance | |

| Kuoma kwemhete, KN/m2 | >8 | |

| Flat test | Haina kuputsika | |

| Longitudinal shrinkage (100 ° С, chengetedza 1h) | <0.3% | |

| Hydraulic test | Tembiricha: 20 ° С; Nguva: 1h; Nominal pressure x2 | Haina kuputsika |

| Tembiricha: 80 ° С; Nguva: 165h; Dzvinyiriro: Nominal pressure x2x0.71 (reduction factor) | ||

| Burst pressure test | Tembiricha: 20 ° С, kuputika kudzvinyirira ≥ zita rekumanikidza x3.0 | Kuputika |

| Oxidation induction nguva (200 ° С), min | ≥20 | |

| *Kuramba kwemamiriro ekunze* Kuwedzerwa kugamuchirwa kwepombi≥3.5J/m2 Mushure mekukwegura simba | Hydraulic bvunzo, mamiriro ekuyedza akafanana nechinhu 3 mune ino tafura | Haina kuputsika |

| Burst pressure test, mamiriro ebvunzo akafanana nechinhu 4 mutafura iyi | Kwete kuputika | |

| Oxidation induction nguva (200 ° С), min | ≥10 | |

*Chete yeblue composite pombi*