Products

Simbi mesh skeleton polyethylene pombi

Application

Mumakore makumi maviri apfuura, mapaipi matsva epurasitiki ave achishandiswa zvakanyanya mumasipala, gasi uye magetsi ekudyara minda yekudyara mvura.Kunyanya nekuenderera mberi optimization uye kuvandudzwa kwe polyethylene polymerization tekinoroji, kune kuwedzera kusimba kwekusimba kwe polyethylene zvinhu.Kuti uwedzere kuwedzera huwandu hwekumanikidza kwepombi dzepurasitiki, kunyanya mumakore achangopfuura, kuburikidza nekutsvagisa tekinoroji yekudyidzana, tekinoroji yesimbi yepurasitiki yakaunzwa yakabudirira kugadzirisa matambudziko epombi yepolyethylene (PE) maererano nedanho rekumanikidza, anti- ngura, uye inobudirira kutenderera dhayamita.Inoshandiswa muhuwandu hwakawanda hwekufambisa kwemvura yekushandisa.

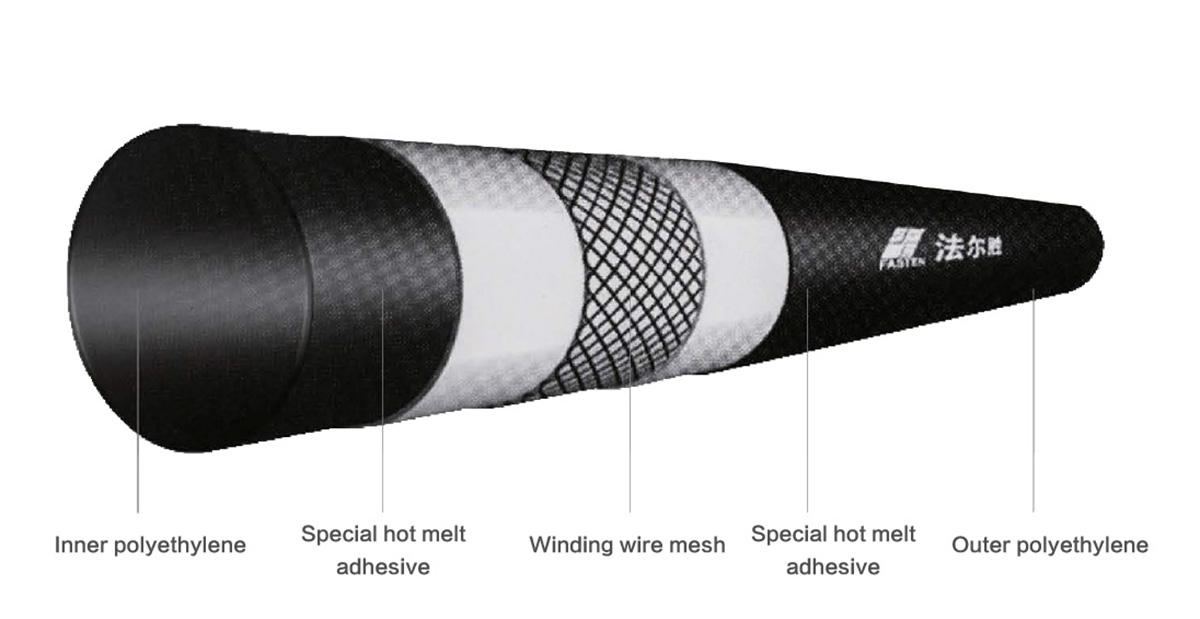

Chimiro: Ichi chigadzirwa ifuremu yakasimbiswa ine core layer yekuramba yakakuvara yakakwirira-yakasimba waya yesimbi mushure mekupotera, uye yakakosha inopisa-inonyungudika glue nepurasitiki zvinosanganiswa kuita pombi yese ne extrusion molding nzira.

Features

Kuitwa kwehupfumi hwepombi

Ichishandisa yakakwira-density polyethylene seyemukati uye yekunze layer zvinhu, simbi mesh skeleton polyethylene plastiki composite pombi ine mashandiro akanaka ezvigadzirwa zvepombi yepolyethylene.Nekuda kwekuita kwesimbi skeleton, iyo inoumbwa pombi yeakaenzana nhanho yekumanikidza ine diki madziro ukobvu pane yakachena pombi dzepurasitiki.Iko kutenderera kunoshanda агеа kwakakura, uye iyo yakanaka corrosion kuramba uye kupfeka kuramba kunovimbisa kuti hupenyu hwesevhisi yepombi сап bе yakareba semakore makumi mashanu, izvo zvinonyatso kuvandudza kushanda kwehupfumi hwepombi.

Simbisa skeleton kuti ibudirire kudzvanya mitswe

Kushandiswa kwesimbi yakakwirira-yakasimba mesh core layer sesimbi inosimbisa skeleton inonyatso kuvharidzira kugadzirwa kwenguva refu kwekutsemuka uye kukurumidza kuparuka kwemidziyo yepolyethylene, uye kune simba repamusoro rekumanikidza (kudzvanywa kwepombi yemvura kunosvika З.5МРа) uye mutorwa сгеер kuramba, Yepamusoro pesimba kuramba, uye maitiro ayo zviratidzo аге yepamusoro polyethylene mapaipi.

Technical Parameters

| Absolute roughness table yemukati memadziro akaenzana nemapombi akasiyana | |||

| Rudzi rwepombi | Kukosha mm | Rudzi rwepombi | Kukosha mm |

| Pombi itsva yesimbi isina musono | 0.04-0.17 | Pombi yesimbi itsva | 0.2-0.3 |

| Simbi furemu epurasitiki composite pombi | 0.0015-0.009 | Pombi yesimbi yekare | 0.5-0.6 |

| Mhangura pombi mune zvakawanda | 0.19 | Galvanized steel | 0.152 |

| Pombi yesimbi yekare | 0.60 | Yakasimbiswa kongiri pombi | 1.8-3.5 |

| Zita rekunze dhayamita | Avhareji yekunze dhayamita | Minimum nominal waya dhayamita | Nominal pressure | |||||

| Dn(mm) | Kutsauka kunobvumirwa | Mm | 0.8 | 1.0 | 1.6 | 2.0 | 2.5 | 3.5 |

| Nominal wall thickness en uye inotenderwa kutsauka kwemadziro ukobvu ey chero nzvimbo/mm | ||||||||

| 50 | +1.2 0 | 0.5 | - | - | 5.0 | 5.5 | 6.0 | 6.5 |

| 63 | +1.2 0 | 0.5 | - | - | 5.5 | 6.0 | 6.5 | 7.0 |

| 75 | +1.2 0 | 0.5 | - | - | 6.0 | 6.5 | 7.0 | 7.0 |

| 90 | +1.4 0 | 0.5 | - | - | 6.5 | 7.0 | 7.5 | 8.0 |

| 110 | +1.5 0 | 0.5 | - | 6.0 | 7.0 | 7.5 | 8.0 | 8.5 |

| 125 | +1.6 0 | 0.6 | - | 6.0 | 7.5 | 8.0 | 8.5 | 9.5 |

| 140 | +1.7 0 | 0.6 | - | 6.0 | 8.0 | 8.5 | 9.5 | 10.5 |

| 160 | +2.0 0 | 0.6 | - | 6.5 | 9.0 | 9.5 | 10.5 | 11.5 |

| 200 | +2.3 0 | 0.6 | - | 7.0 | 9.5 | 10.5 | 12.5 | 13.0 |

| 225 | +2.5 0 | 0.6 | - | 8.0 | 10.0 | 10.5 | 12.5 | - |

| 250 | +2.7 0 | 0.6 | 8.0 | 10.5 | 12.0 | 12.0 | 13.0 | - |

| 315 | +2.8 0 | 0.6 | 9.5 | 12.0 | 13.0 | 13.0 | 14.5 | - |

| 355 | +3.0 0 | 0.8 | 10.0 | 12.5 | 14.0 | - | - | - |

| 400 | +3.2 0 | 0.8 | 10.5 | 13.0 | 15.0 | - | - | - |

| 450 | +3.2 0 | 0.8 | 11.5 | 14.0 | 16.0 | - | - | - |

| 500 | +3.2 0 | 0.8 | 12.5 | 16.0 | 18.0 | - | - | - |

| 560 | +3.2 0 | 0.8 | 17.0 | 20.0 | 21.0 | - | - | - |

| 630 | +3.2 0 | 0.8 | 20.0 | 22.0 | 24.0 | - | - | - |

| 710 | +3.8 0 | 1.0 | 23.0 | 26.0 | - | - | - | - |

| 800 | +3.8 0 | 1.0 | 27.0 | 30.0 | - | - | - | - |

| Ongorora: Zvigadzirwa zvinoreva kuisirwa kweGB/T32439, CJ/T189, HG/T4586 mazinga enyika uye indasitiri zviyero. | ||||||||