Products

Perforated simbi mutsetse PE pombi For gasi

Application

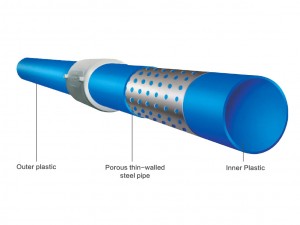

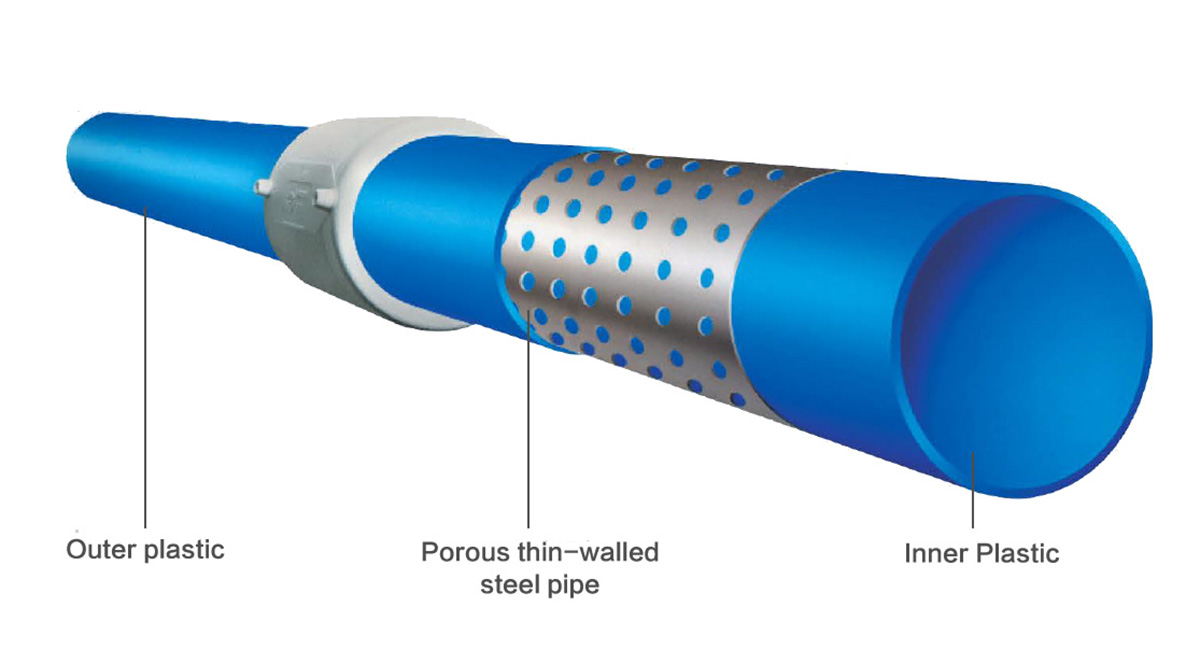

Perforated simbi strip polyethylene composite pombi inogadzirwa neinotonhora-yakakungurutswa strip simbi uye thermoplastics seyakagadzirwa, uye porous yakatetepa-yakavakirwa simbi mapaipi akaumbwa neargon arc butt welding kana plasma spiral welding anoshandiswa sekusimbisa. Iwo ekunze uye emukati akaturikidzana ane maviri-sided composite thermoplastics. Rudzi rutsva rwepombi yekumanikidza pombi, Nekuti iyo porous yakatetepa-yakavakirwa simbi pombi yekusimbisa yakaputirwa muinoenderera thermoplastic, iyi inoumbwa pombi haingokunda zvakakanganisika zvepombi dzesimbi nemapombi epurasitiki, asiwo ine kusimba kwepombi dzesimbi uye ngura. kushorwa kwepombi dzepurasitiki. Ndiyo mhinduro ye petroleum nemakemikari maindasitiri. Iyo pombi inodiwa nekuchimbidza yemapombi makuru uye epakati-dhayamita akaomeswa muminda yemishonga, chikafu, migodhi, gasi nemimwe minda. Iri zvakare shanduko yekuvandudza tekinoroji kugadzirisa pombi huru yekuvaka uye kupihwa kwemvura yemanisipala. Irwo rudzi rutsva rwepombi inosanganiswa mu21stzana remakore.

Features

Hutsanana kuita

Indekisi yehutsanana uye kuchengetedzeka kweiyo perforated simbi strip plastiki composite pombi inosangana nezvinodiwa zveGB9687 "Hygienic Standard for Polyethylene Molded Products for Food Packaging" uye GВ/Т17219 "Safety Evaluation Standard for Drinking Water Distribution Equipment and on Equipment and Protective Materials". Ndiyo yakanakisa inotsiva pombi yakabatiswa uye pombi yakakandwa-simbi.

Smooth mukati memadziro uye kutenderera kwekuita

Rusvingo rwemukati rwe mesh simbi bhandi repurasitiki rinoumbwa pombi inotsvedzerera, uye hutsinye hwacho hunongova 1/20 chete yepombi yesimbi. Iyo yekufambisa simba pasi pemamiriro akafanana inenge 30% yakakwirira kupfuura iyo yepombi yesimbi.

Technical Parameters

| Tsanangudzo saizi, kutsauka uye kudzvanywa kwezita: kusangana nezvinodiwa zveMinistry yekuvaka chiyero CJ/T181-2003. | |||||

| Zita rekunze dhayamita uye kutsauka | Nominal rusvingo ukobvu uye kutsauka | Kunze kwekutenderera | Nominal pressure | Minimum S kukosha | Hurefu nekutsauka |

| Dn(mm) | En(mm) | Mm | Mpa | Mm | mm |

| 50+0.5 0 | 4.0+0.5 9 | 1.0 | 1.0 | 1.5 | 6000+20 0 9000+20 0 12000+20 0 |

| 60+0.6 0 | 4.5+0.6 0 | 1.26 | 1.0 | 1.5 | |

| 75+0.7 0 | 5.0+0.7 0 | 1.5 | 1.0 | 1.5 | |

| 90+0.9 0 | 5.5+0.8 0 | 1.8 | 1.0 | 1.5 | |

| 110+1.0 0 | 6.0+0.9 0 | 2.2 | 1.0 | 1.5 | |

| 140+1.1 0 | 8.0+1.0 0 | 2.8 | 1.0 | 2.5 | |

| 160+1.2 0 | 10.0+1.1 0 | 3.2 | 1.0 | 2.5 | |

| 200+1.3 0 | 11.0+1.2 0 | 4.0 | 1.0 | 2.5 | |

| 250+1.4 0 | 12.0+1.3 0 | 5.0 | 0.8 | 3.5 | |

| 315+1.6 0 | 13.0+1.4 0 | 6.3 | 0.8 | 3.5 | |

| 400+1.6 0 | 15.0+1.5 0 | 8.0 | 0.8 | 3.5 | |

| 500+1.7 0 | 16.0+1.6 0 | 10.0 | 0.6 | 4.0 | |

| 630+1.8 0 | 17.0+1.7 0 | 12.3 | 0.6 | 4.0 | |

| Cherechedza: Kudzvinyirirwa kwezita repombi inosanganiswa ndiyo yakanyanya kudzvinyirira inobvumirwa kuti pombi itakure mvura pa20 ° С. Kana tembiricha ichichinja, kumanikidza kwekushanda kunofanirwa kugadziridzwa zvinoenderana neiyo tembiricha yekumanikidza coefficient yezvinhu zvakasiyana. S kukosha: chinhambwe kubva kunze kwedhayamita yekusimbisa kusvika kune kunze kwepombi. | |||||

| Zvenyama uye zvemuchina kuita zvinodiwa | ||

| Project | Performance | |

| Kuoma kwemhete, KN/m2 | >8 | |

| Longitudinal shrinkage (110 ° С, chengetedza 1h) | <0.3% | |

| Hydraulic test | Tembiricha: 20 ° С; Nguva: 1h; Nominal pressure x2 | Haina kuputsika |

| Tembiricha: 80 ° С; Nguva: 165h; Dzvinyiriro: Nominal pressure x2x0.71 (reduction factor) | ||

| Burst pressure test | Tembiricha: 20 ° С, kuputika kudzvinyirira ≥nominal pressure x3.0 | Kuputika |

| Oxidation induction nguva (200 ° С), min | >20 | |

| Inopikisa kukurumidza kushushikana kwekuwedzera (80 ° С, 4.0Mpa) / h | >1000 | |

| Kuramba kwemamiriro ekunze (mushure mekunge pombi yagamuchira≥3.5GJ/m2kuchembera simba) | Sangana nezvinodiwa zvezvinhu 2,3 uye 4 mune ino tafura, uye inogona kuchengetedza yakanaka welding performance | |